Home /

Applications & Materials

Sample Polypico system applications from the Life Sciences & Medical and Industrial & Engineering sector. Plus view a range of materials compatible with our technology.

Life Sciences & Medical Applications

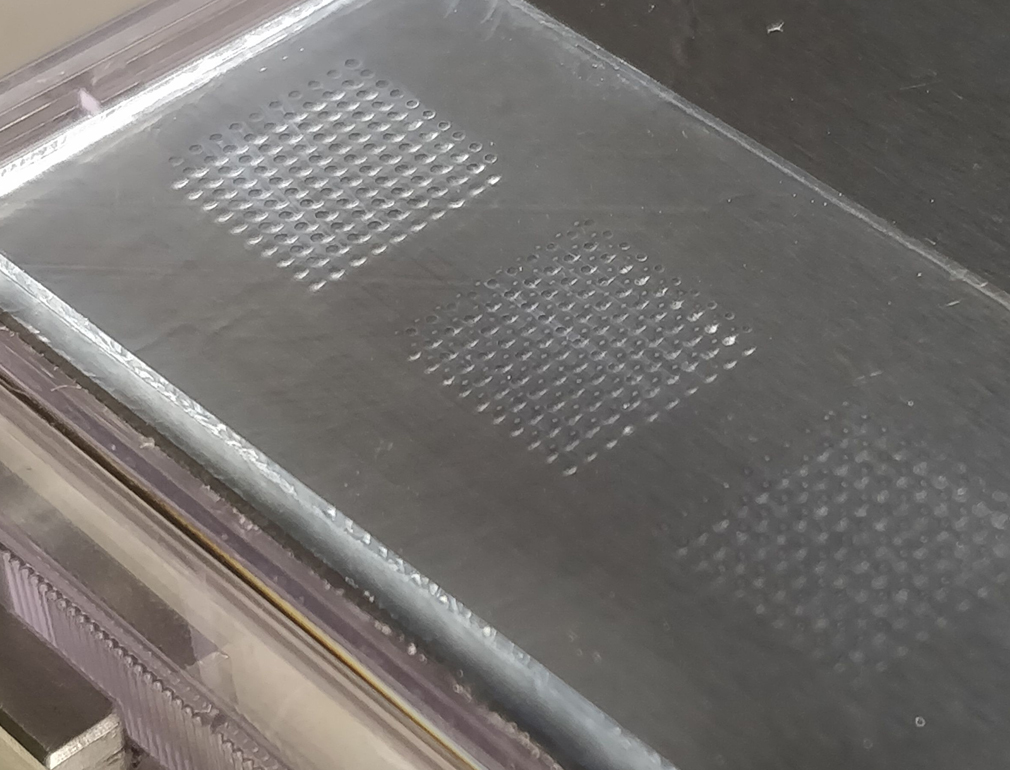

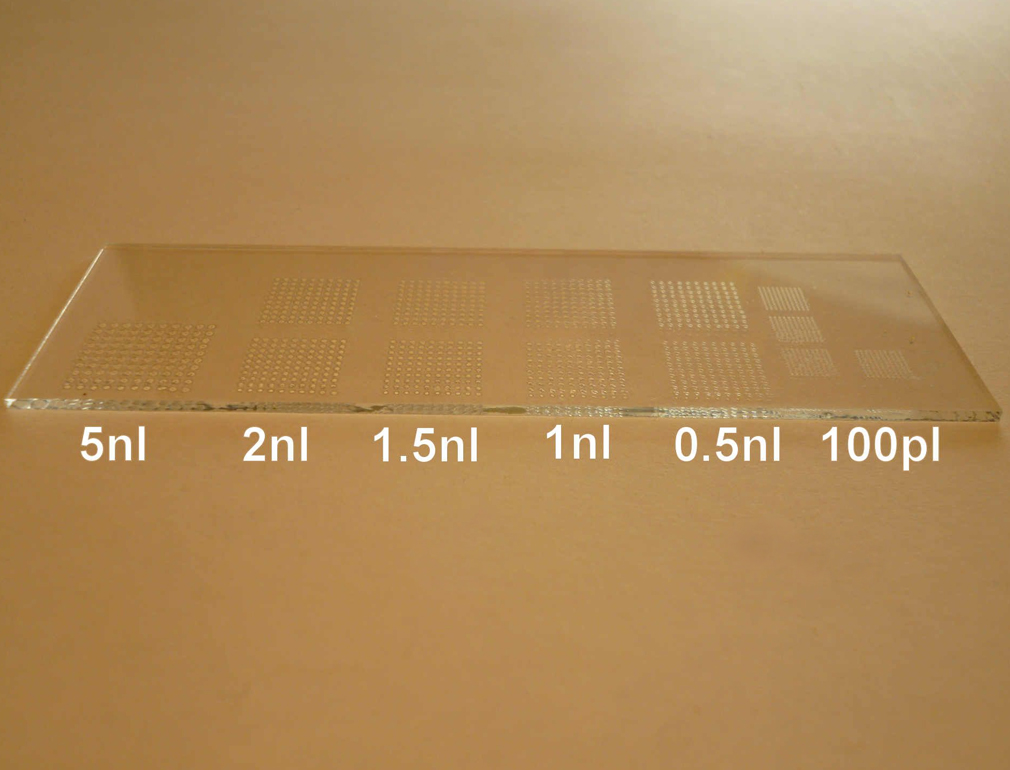

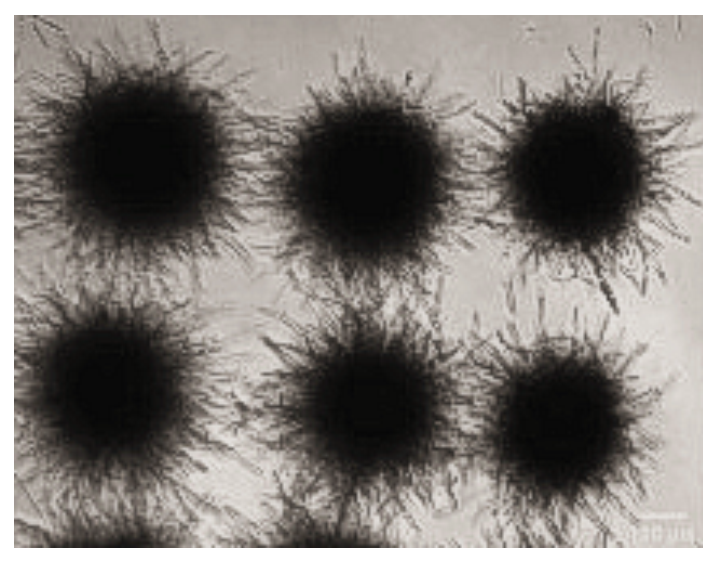

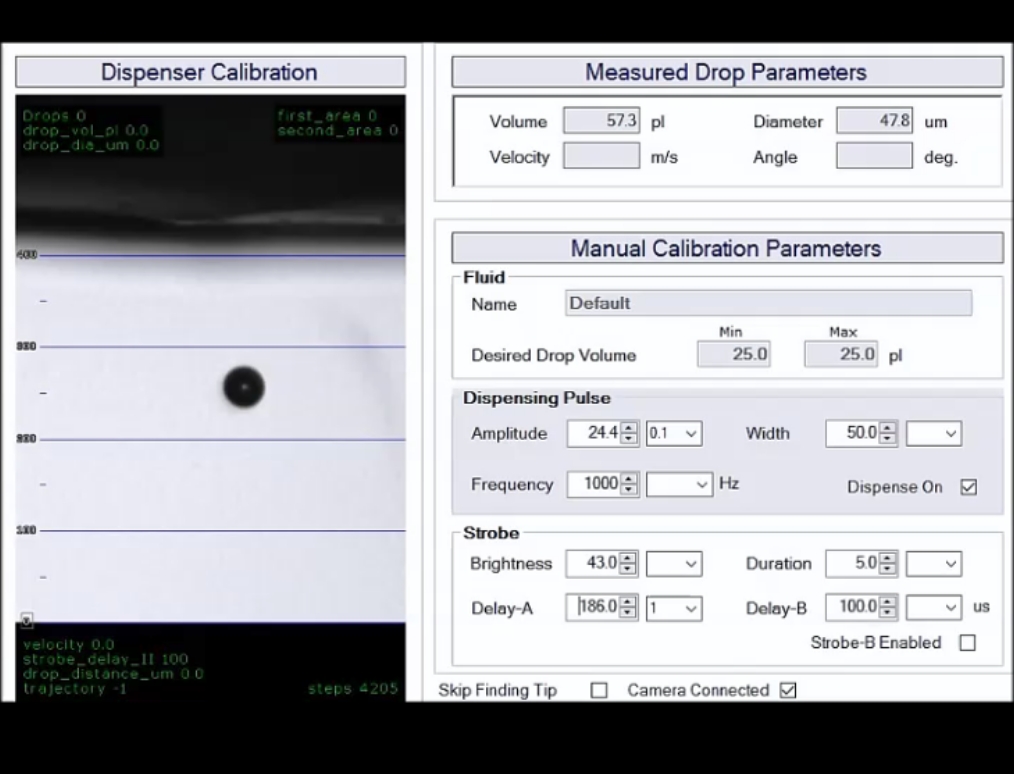

Microscale Arrays for the Characterization of Neutrophil Swarming

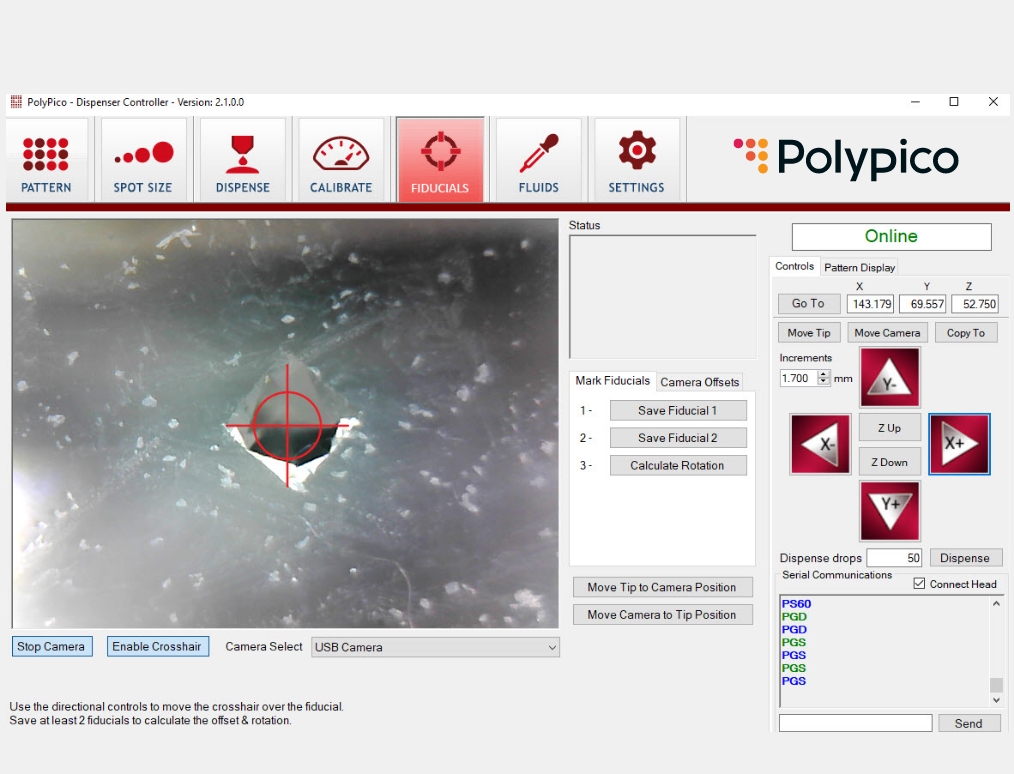

Traditional assays do not reliably recapitulate swarming behavior which has made swarming difficult to study in vitro. The Hopke lab, therefore utilizes a novel microscale array system to study swarming. This assay, which uses the Pico E dispensing system, allows to design and dispense arrays of hundreds or thousand individual fluid droplets onto glass slides to form the arrays. Each of these droplets then binds the microbes of interest to form individual and identical microbial clusters, each of which can induce a swarming response for study, enabling the study of hundreds of swarms in parallel.

Download the application & information about Pico E:

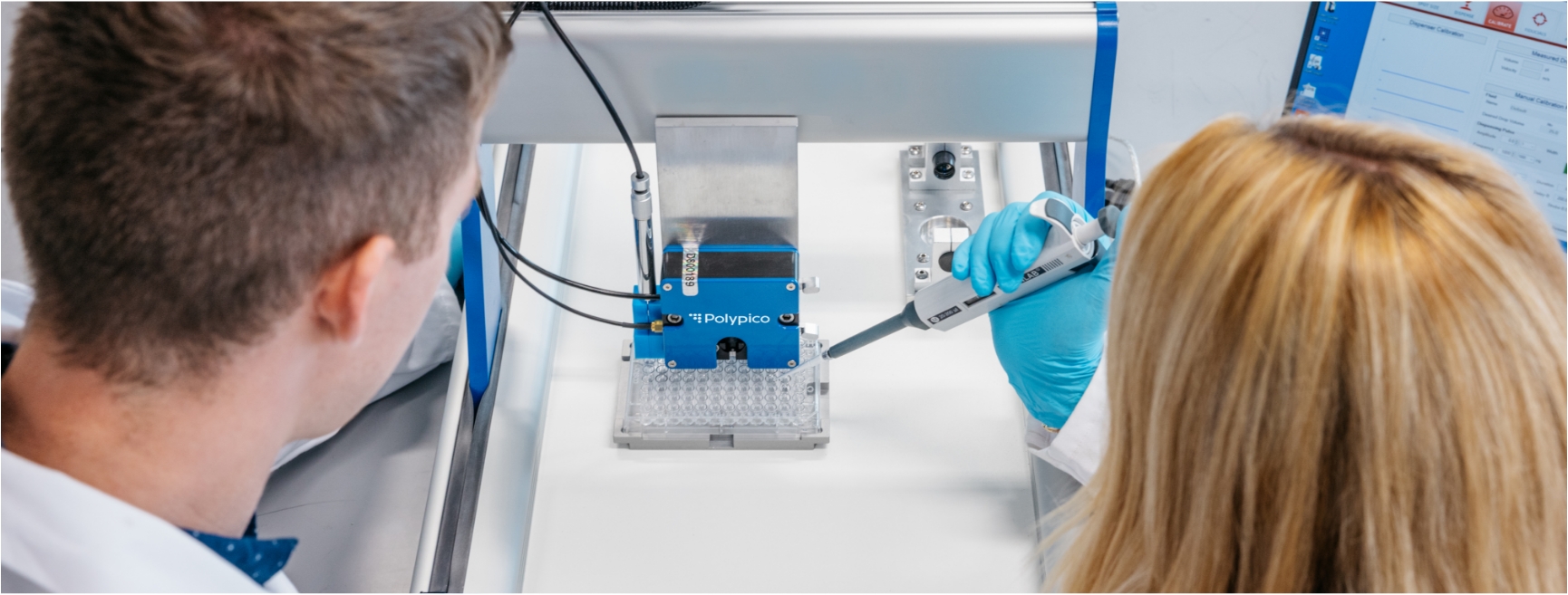

Sensor Fabrication

Antibodies/nucleic acid sequences/biological reagents can be successfully printed or patterned onto substrates to create devices such as environmental sensors and Point-of-Care diagnostic devices, and lateral flow tests.

Systems used to deliver this application include:

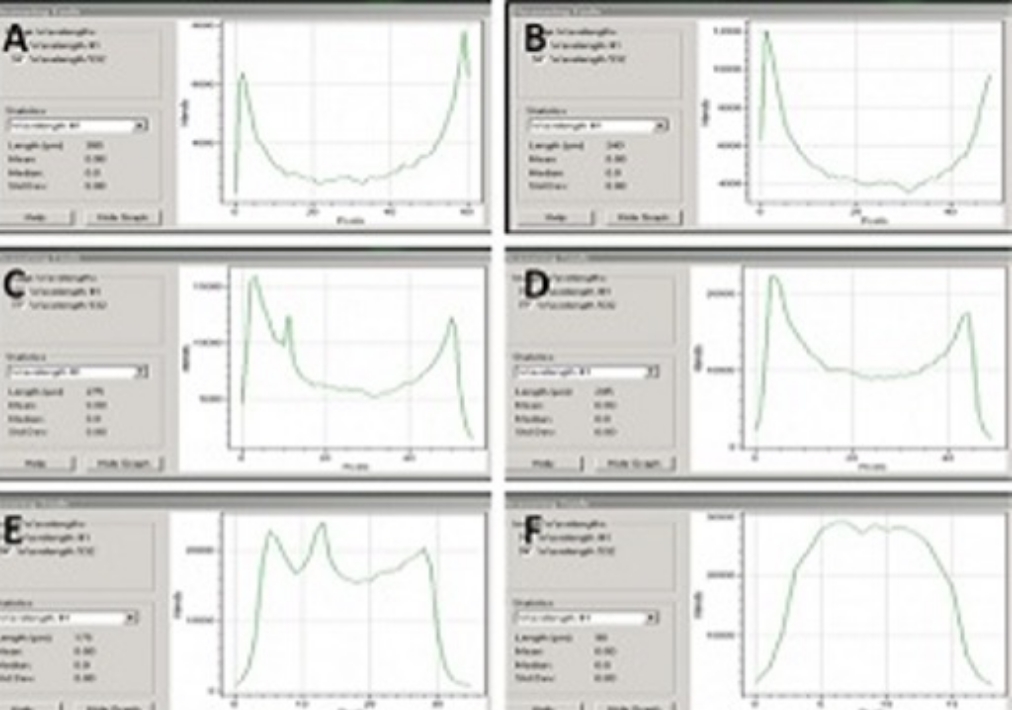

Microarray Printing

Ideally suited for generating high content antibody and protein arrays, delivering clearly visible, uniform and reproducible arrays. The first image shows an antibody array which was dispensed to test reproducibility and for statistical analysis. The scans A-F represent ’50 drops’ through to ‘1 drop’. These images clearly indicate that in particular F (1 spot) produces excellent results, note the absence of the traditional ‘coffee ring’ or ‘doughnut effect’.

Systems used to deliver this application include:

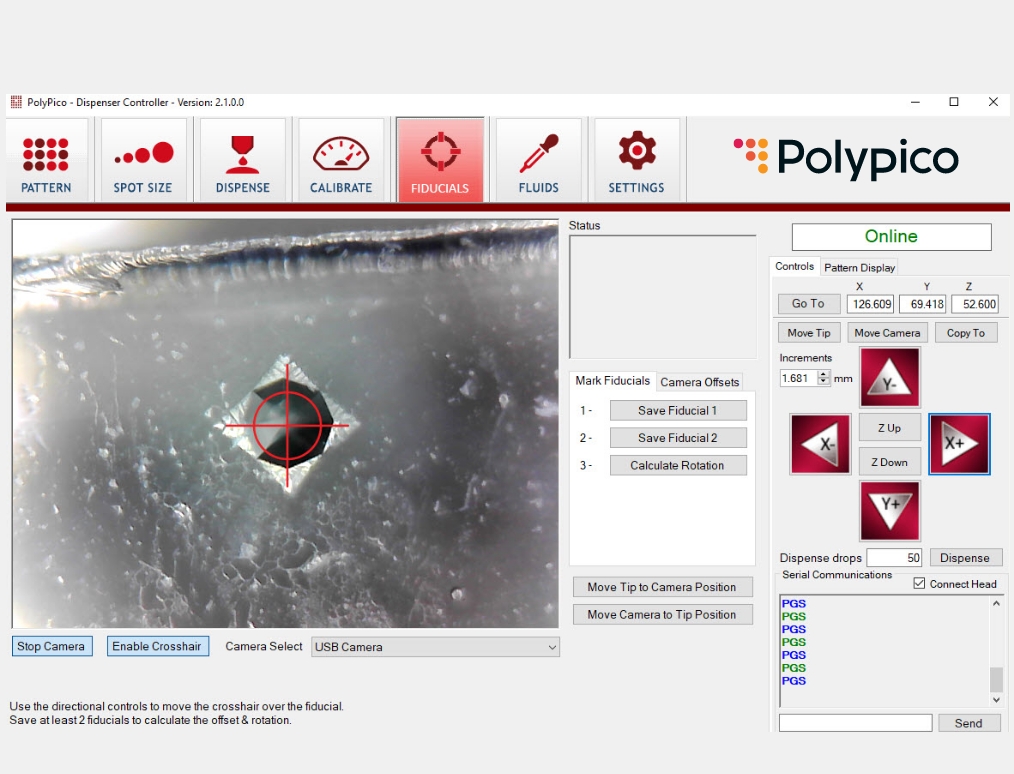

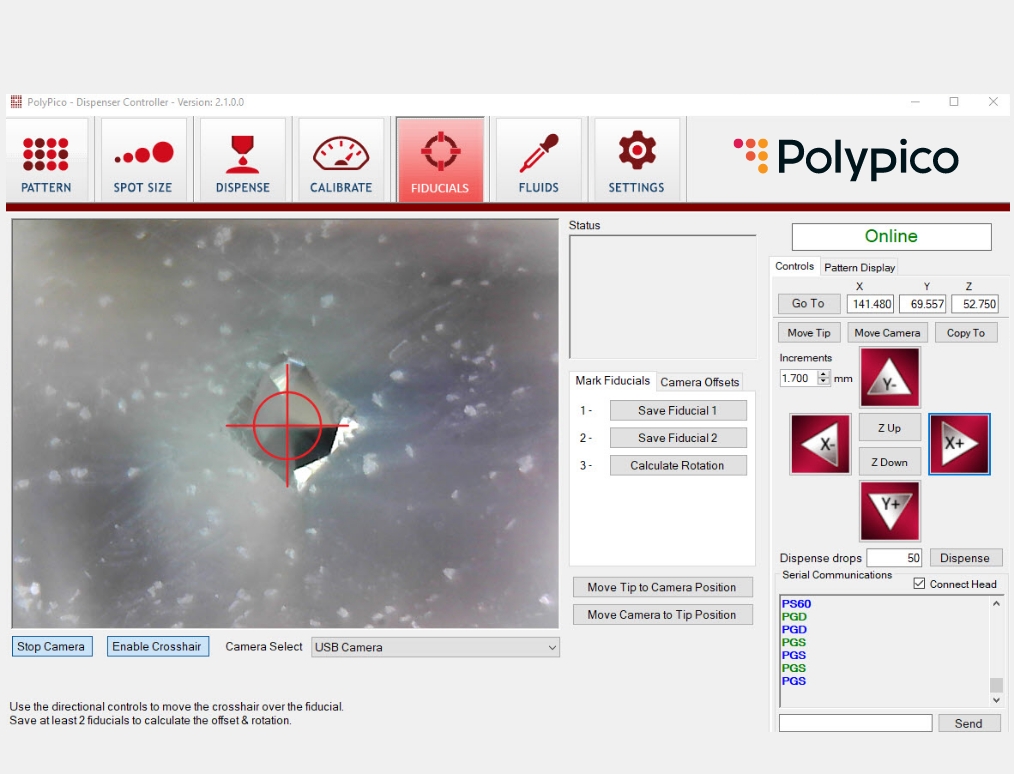

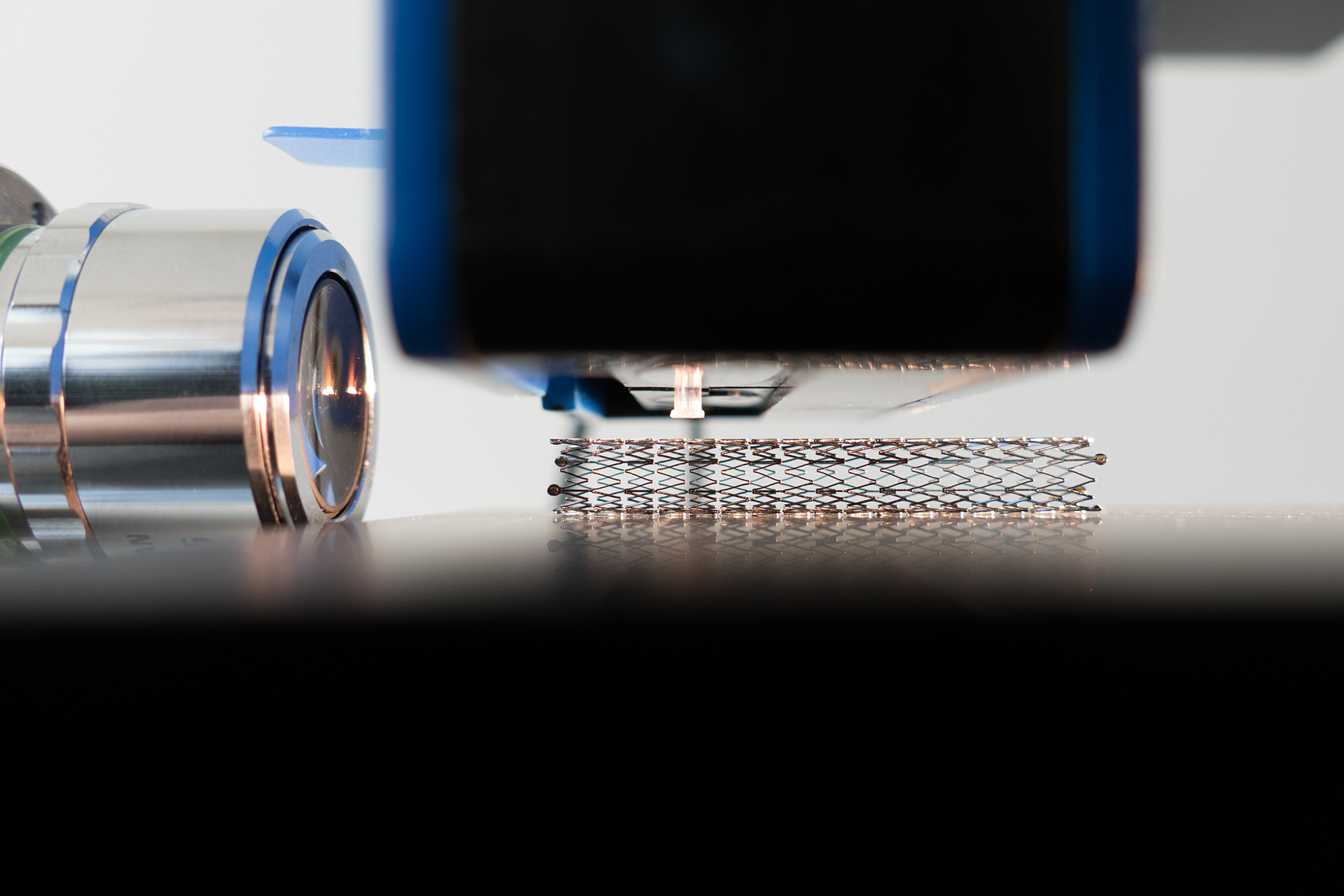

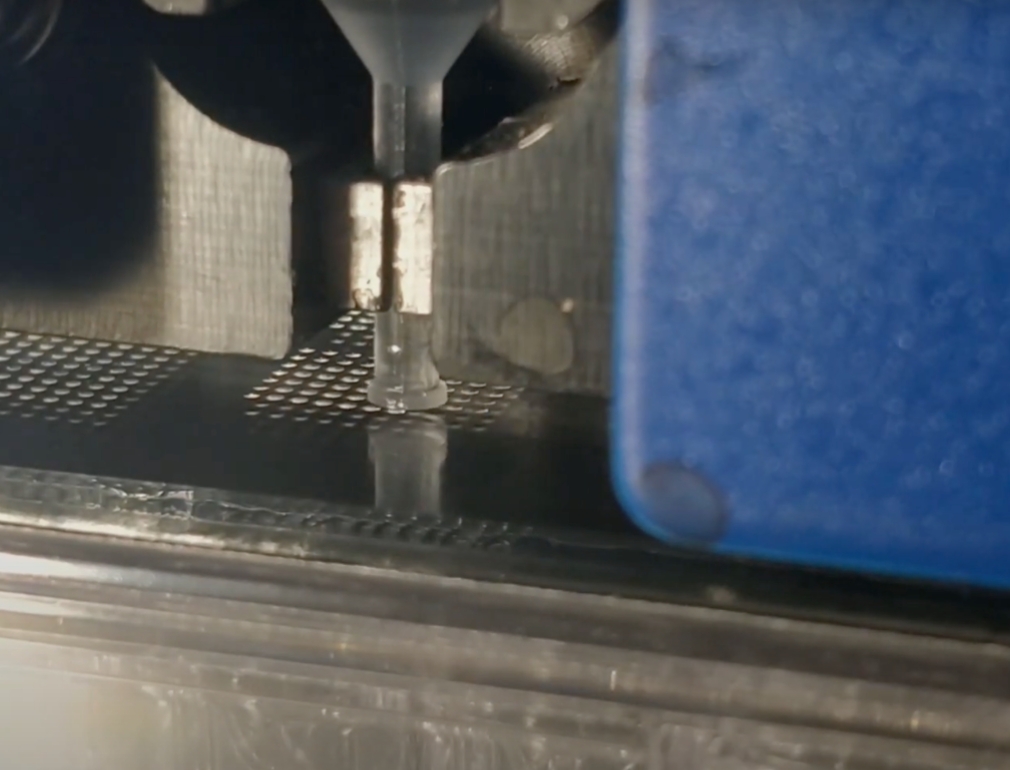

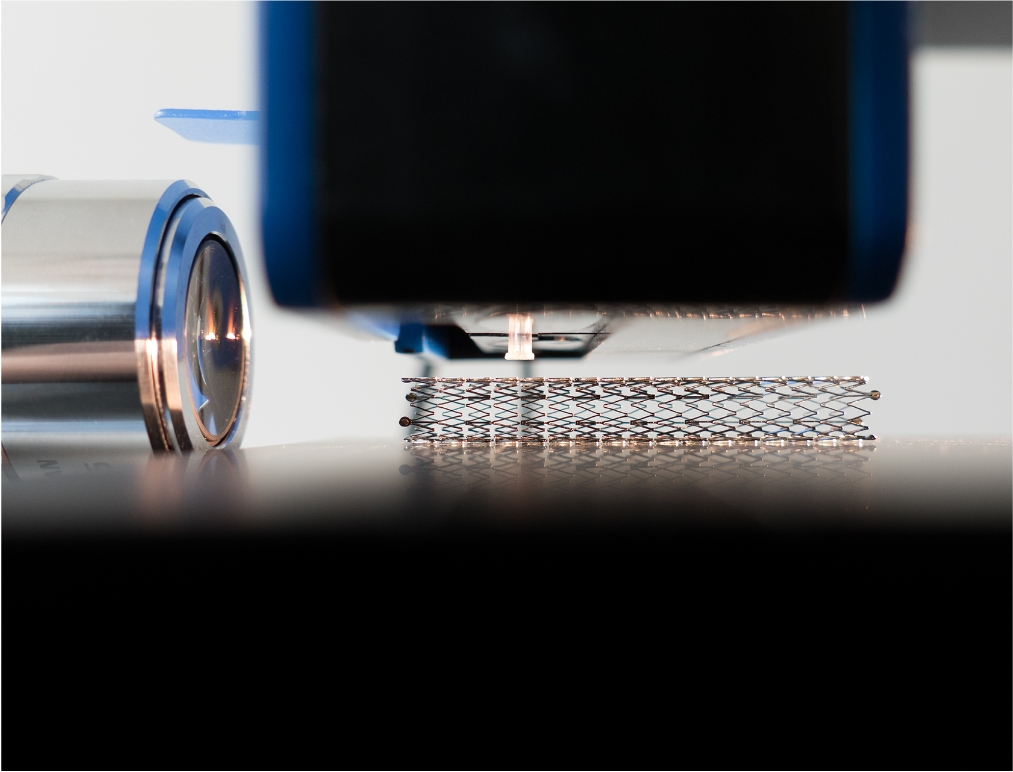

Microneedle Manufacture

Polypico dispensing systems have been used to advance the manufacture and R&D of drug and vaccine microneedles. Sample applications include filling microneedle patches or dispensing directly onto preformed microneedles.

Systems used to deliver this application include:

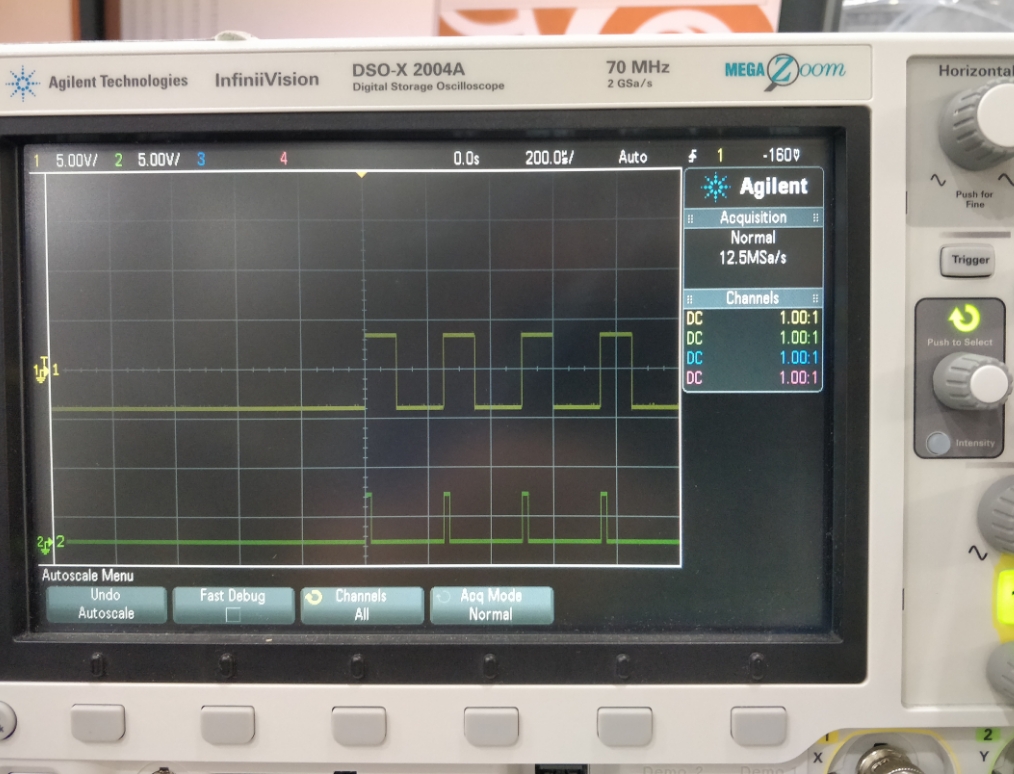

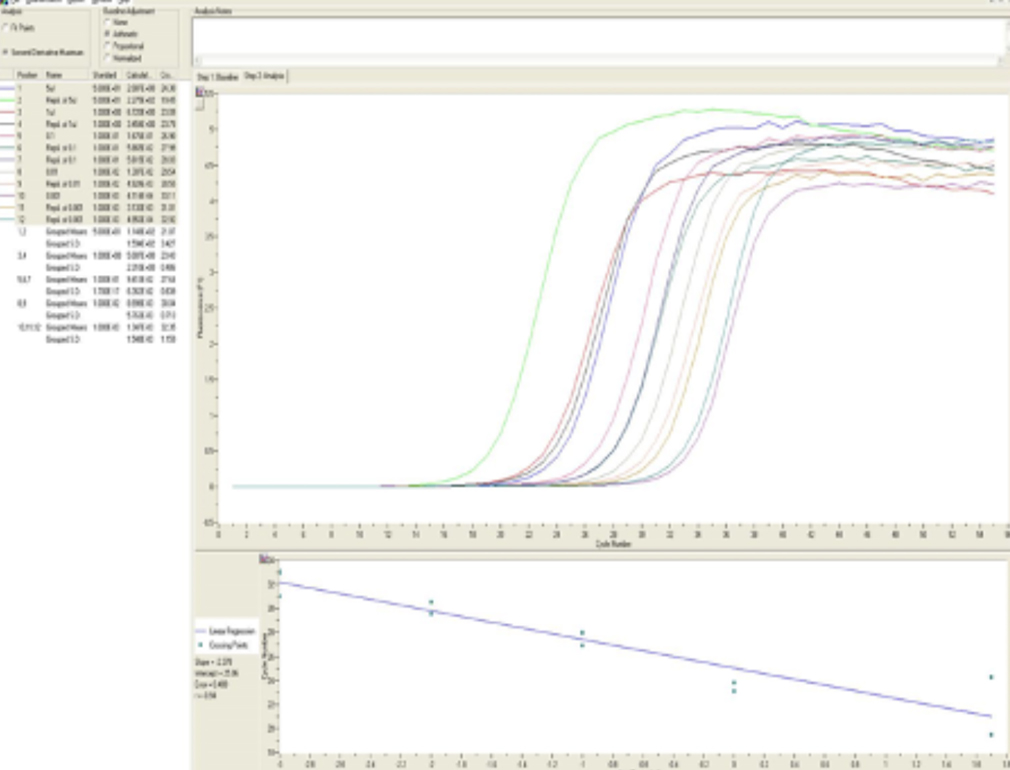

PCR

PolyPico technology can be used in real-time PCR, and dPCR applications, where various quantities of DNA are amplified/quantified. Example application curves are illustrated for various protocols.

5 ul of cDNA delivered into a test sample

1 ul of cDNA delivered into a test sample

0.1 ul of cDNA delivered into a test sample

0.01 ul of cDNA delivered into a test sample

0.001 ul of cDNA delivered into a test sample

Systems used to deliver this application include:

Drug Discovery

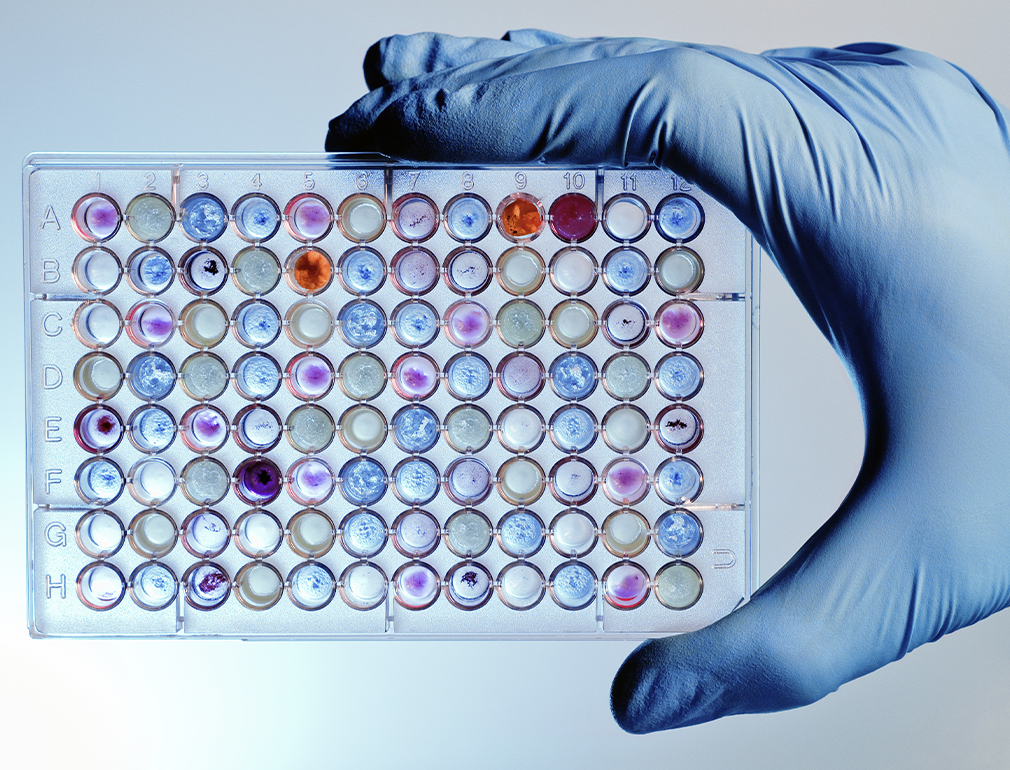

Polypico dispensing systems can be used to dispense small molecules and maximise sample usage by working in the picolitre volumes.

Systems used to deliver this application include:

Living Cells

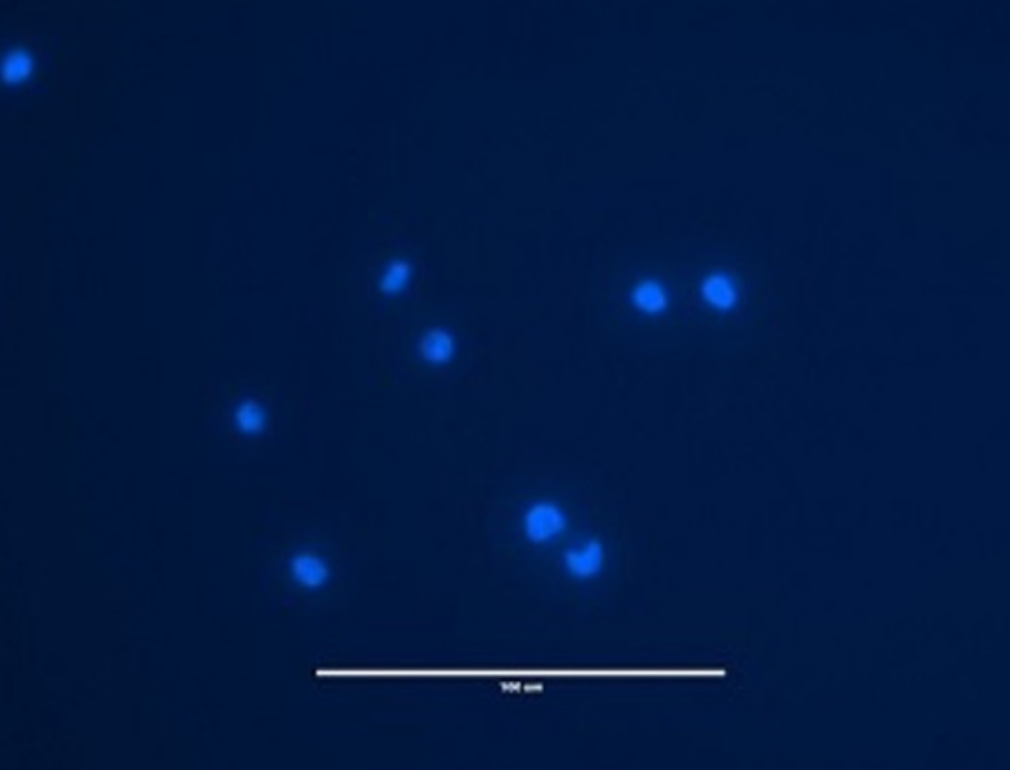

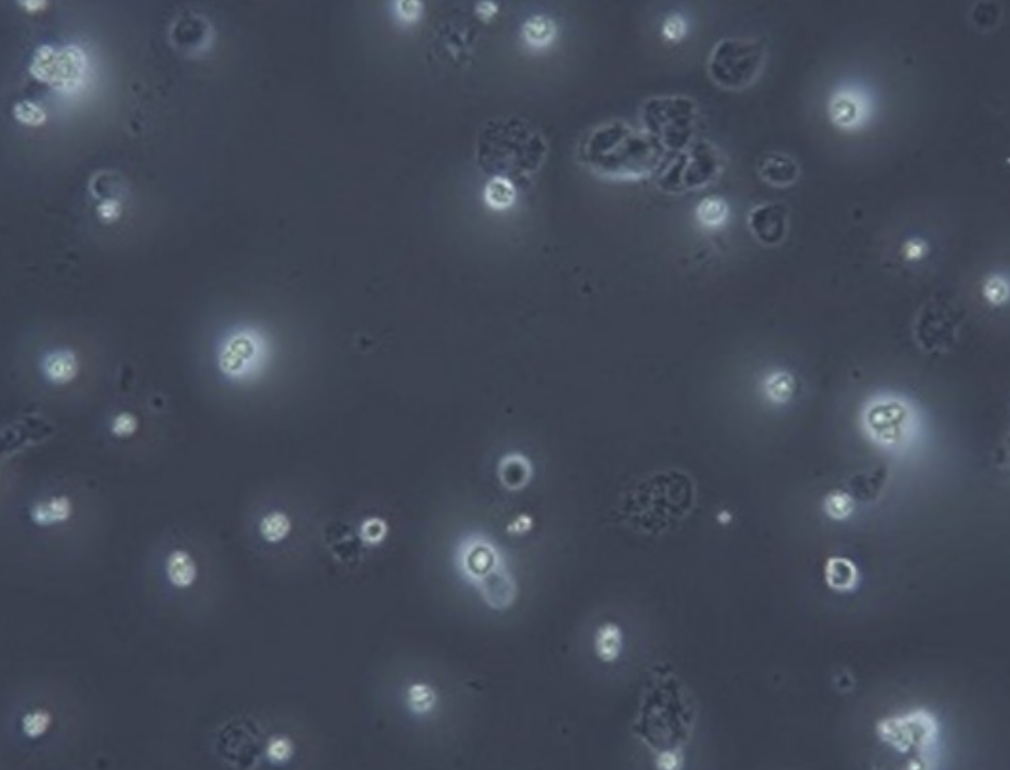

Polypico dispensing technology can be used to dispense living cells. The first image shows Chinese Hamster Ovary (CHO) cells dispensed using Polypico technology into micro-well plates. The second image shows stem cells which were dispensed onto slides and into well-plates, while maintaining their viability. The third shows dispensing stem cells onto a Transmission Electron Microscope grid.

Systems used to deliver this application include:

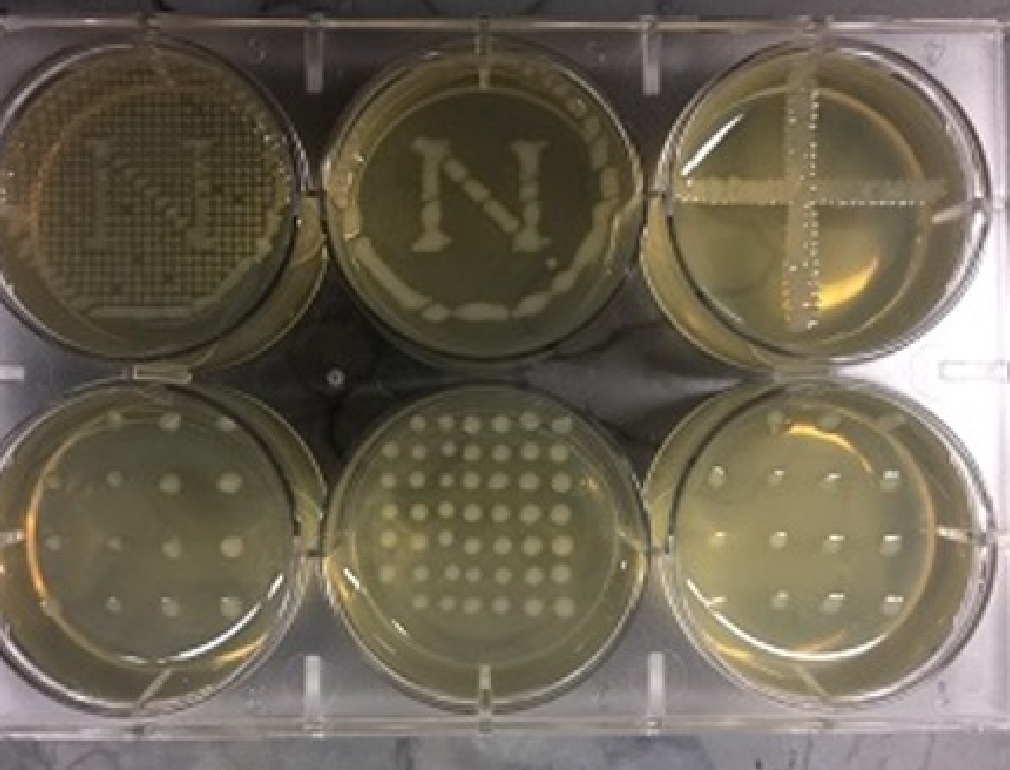

Bacteria Dispensing

Deposit controlled amounts of bacteria, for example our systems can be used to ‘print’ bacteria in petri dishes which have then been allowed to colonize.

Systems used to deliver this application include:

Protein Crystallography

Polypico dispensers can be used to dispense protein microcrystals in order to facilitate structural analysis and R&D projects.

Systems used to deliver this application include:

Industrial & Engineering Applications

Medical / Optical / MEMS Device Manufacture

Precision devices which require ultra-high accuracy of both volume and placement of fluid deposited can benefit from Polypico technology. Our technology allows adhesives and coatings to be accurately placed with precision in the order of microns and deposited in the picolitre volume range.

Dispensing of Adhesive

Accurately deposit low viscosity (<30cps) adhesives in drops at a diameter of 0.0254mm. Low viscosity adhesives, such as cyanoacrylate, can remain in the dispensing cartridge for several days without curing or clogging the dispensing cartridge.

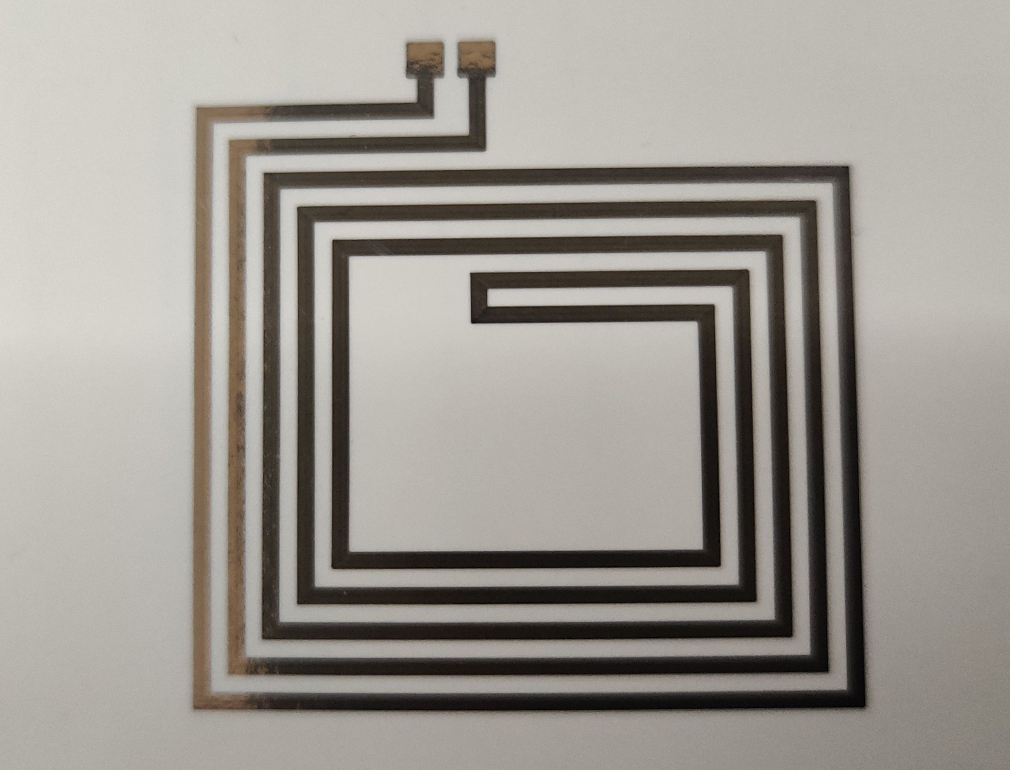

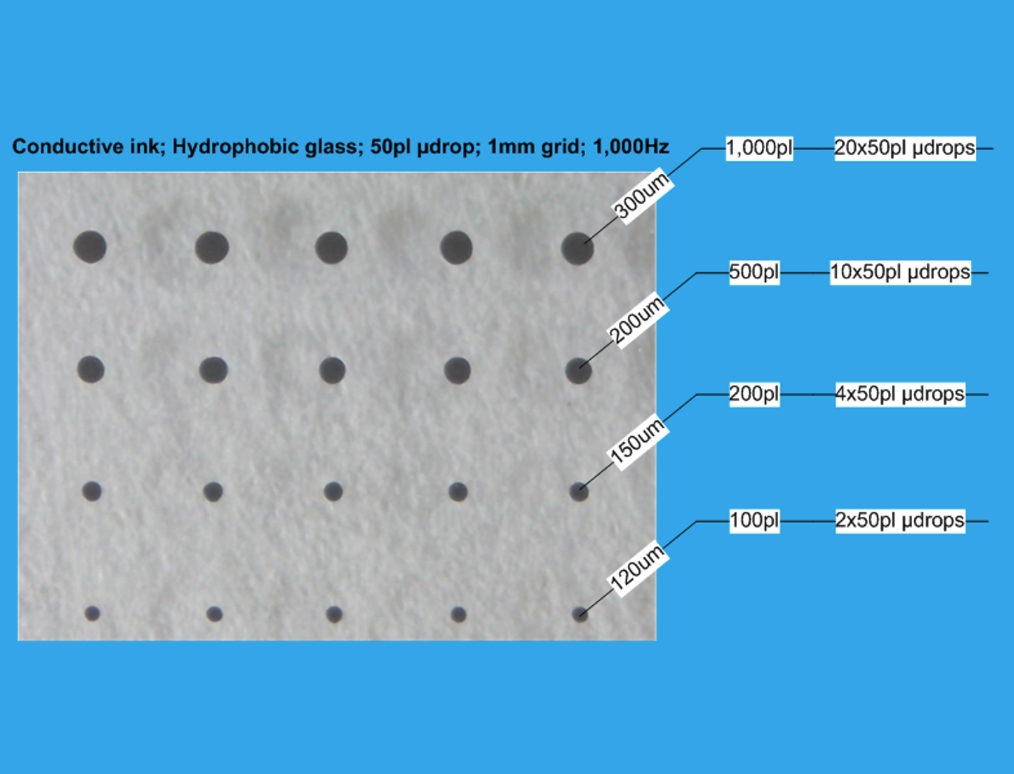

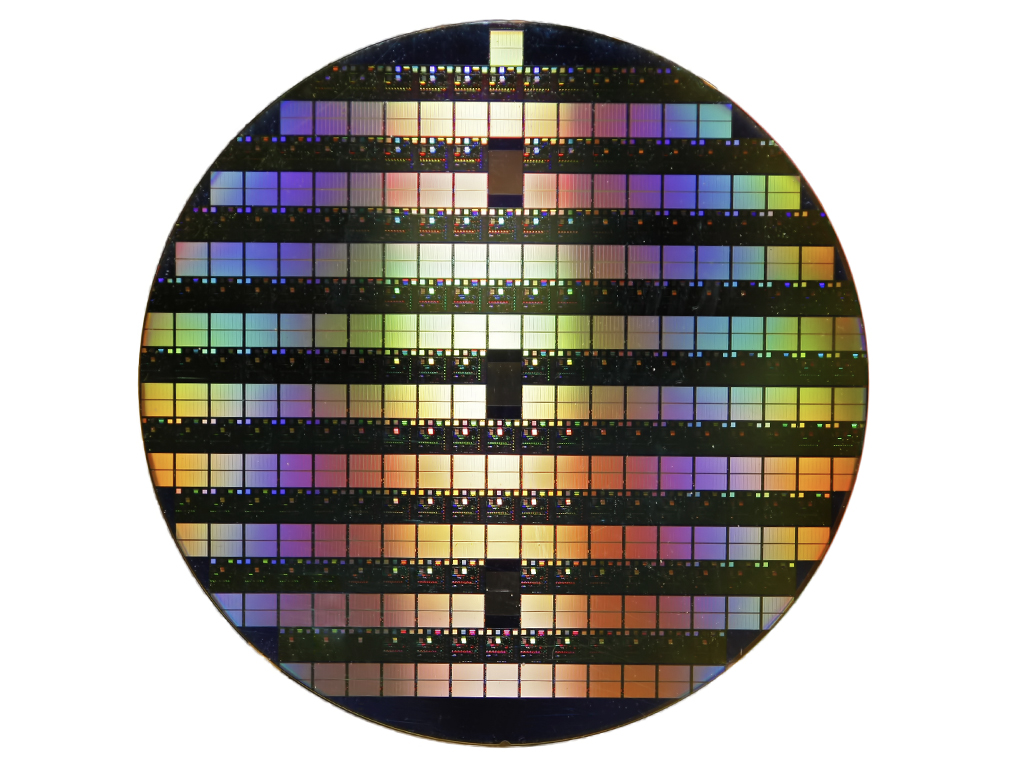

Circuit / Electrode Manufacture

Print silver and carbon based conductive inks to form electrical circuits and electrodes. Diverse active electrode materials may be deposited to form sensors or printed electronics.

Contact Angle Drop Measurement

Integrating our technology into your application or instruments enables the use of disposable high precision dispensing technology.

Application of Coatings / Creation of Reference Standards

Dispense coatings, active pharmaceutical ingredients, radio-active isotopes, nano-materials and lubricants with ultra-high precision both in terms of the volume and the location of the deposition.

Serial Dilutions and Stock References

Create serial dilutions and reference standards with super precision in the picolitre volume range. Acids, bases and other solvents can be dispensed with ease.

Fundamental Science

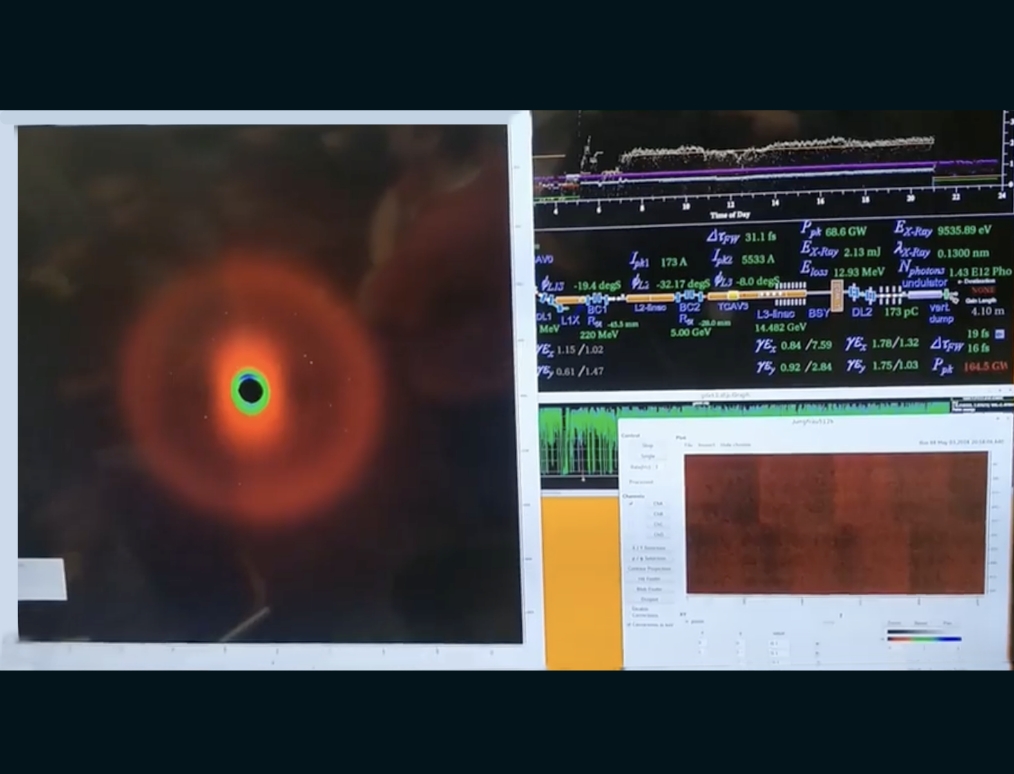

Print samples of material for analysis onto TEM grids, arrays and other substrates or delivered directly to high energy beams such as X-Ray Free-Electron Lasers.

Manufacturing Processes

Integrate Polypico technology directly into manufacturing lines to deliver precise volumes of material in a reliable and robust manner.

Materials

Biologically active

- DNA / RNA / PNA

- Proteins / antibodies

- Living cells e.g. stem cells, cancer cells, etc.

- Protein microcrystals

- Material solutions e.g. aqueous / DMSO / ethanol / nitric acid / etc.

- Small molecules in solution, API, etc.

- Other biologically active materials

Non-biologically active

- Adhesives e.g. cyanoacrylate

- Radioactive isotopes

- Conductive Inks e.g. carbon/silver based

- Coatings / lubricants

- Nano-materials, carbon nano-tubes

- Other functional materials

Contact

Request

a Callback.

Our dispensing specialists are happy to share their

expertise and advise on the ideal solution for your

application.